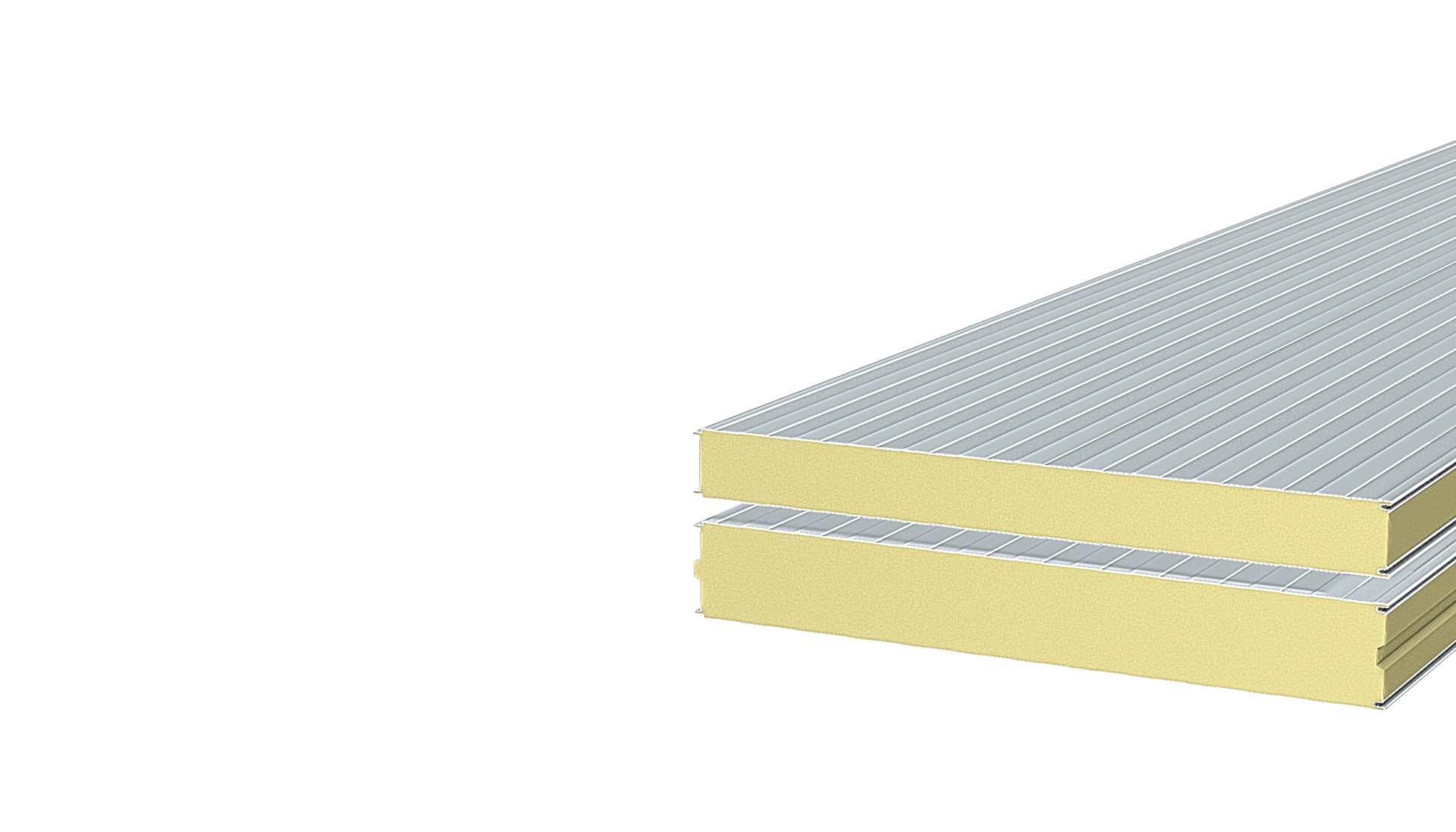

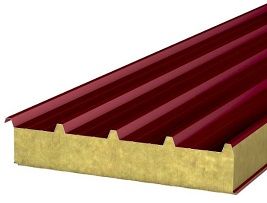

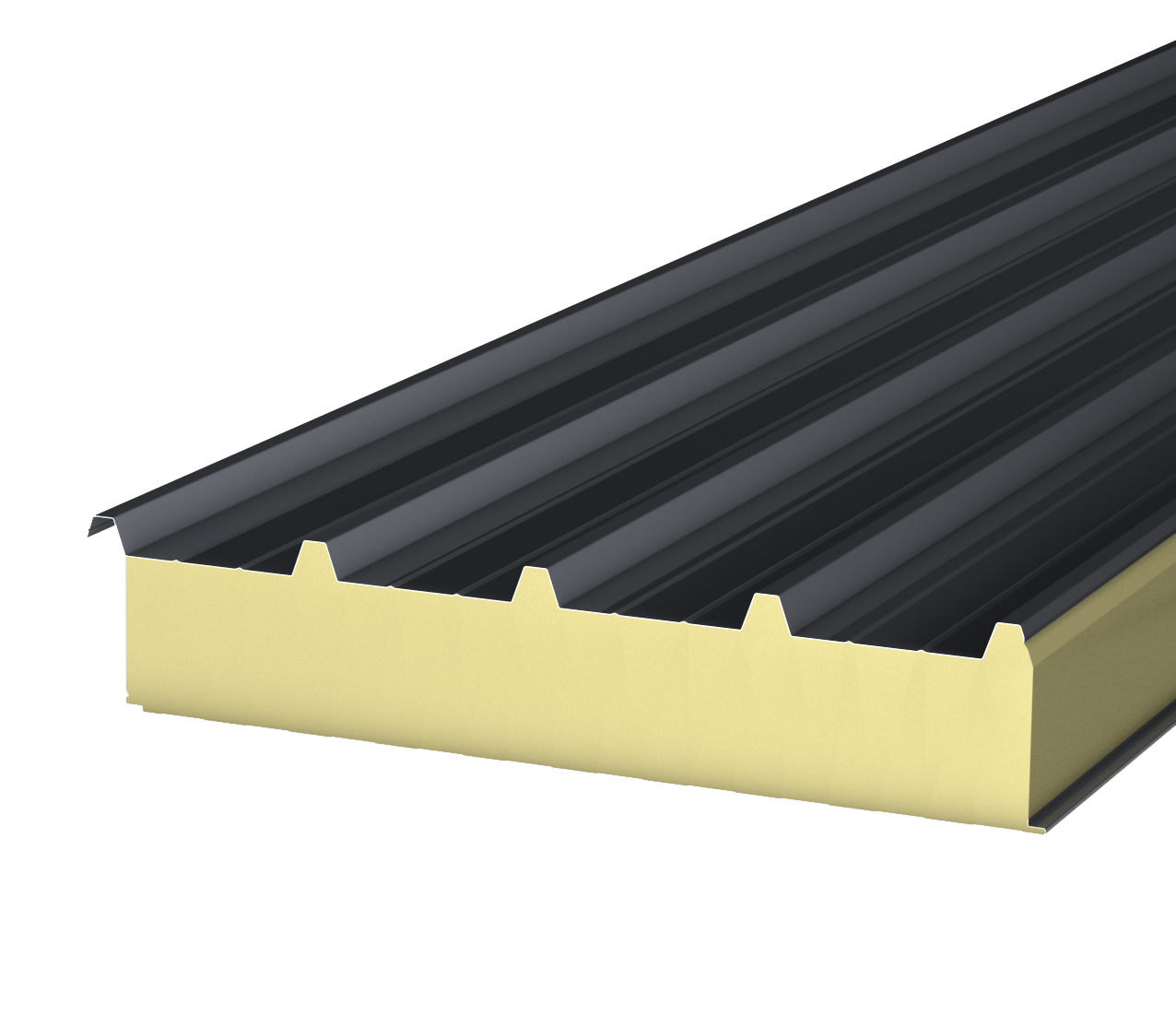

Lightly profiled sandwich panels with PIR core Tenax W PIR S/T

- Custom made solutions

- Short delivery time (3-4 weeks)

- Engineering and designing support to clients

- Project management support during construction

- Less cutting work and waste at building site (available panel widths are from 0,6 till 1,2 m)

- Easy to replace the insulation core of panels after project design (for example, from MW to PIR)

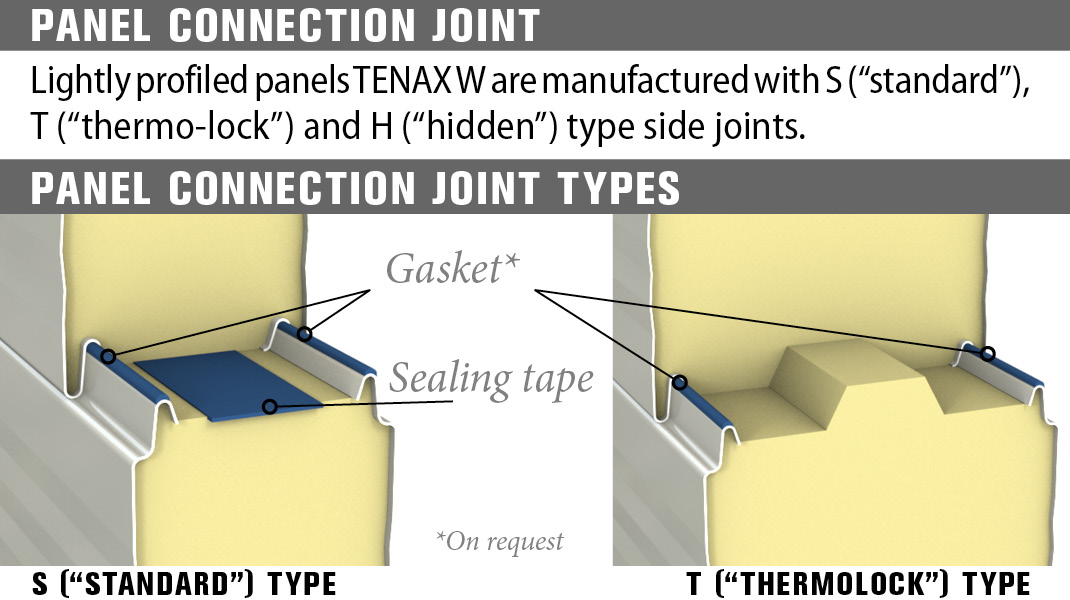

- Panel joints are fully compatible with each other (MW, PIR, PUR and EPS)

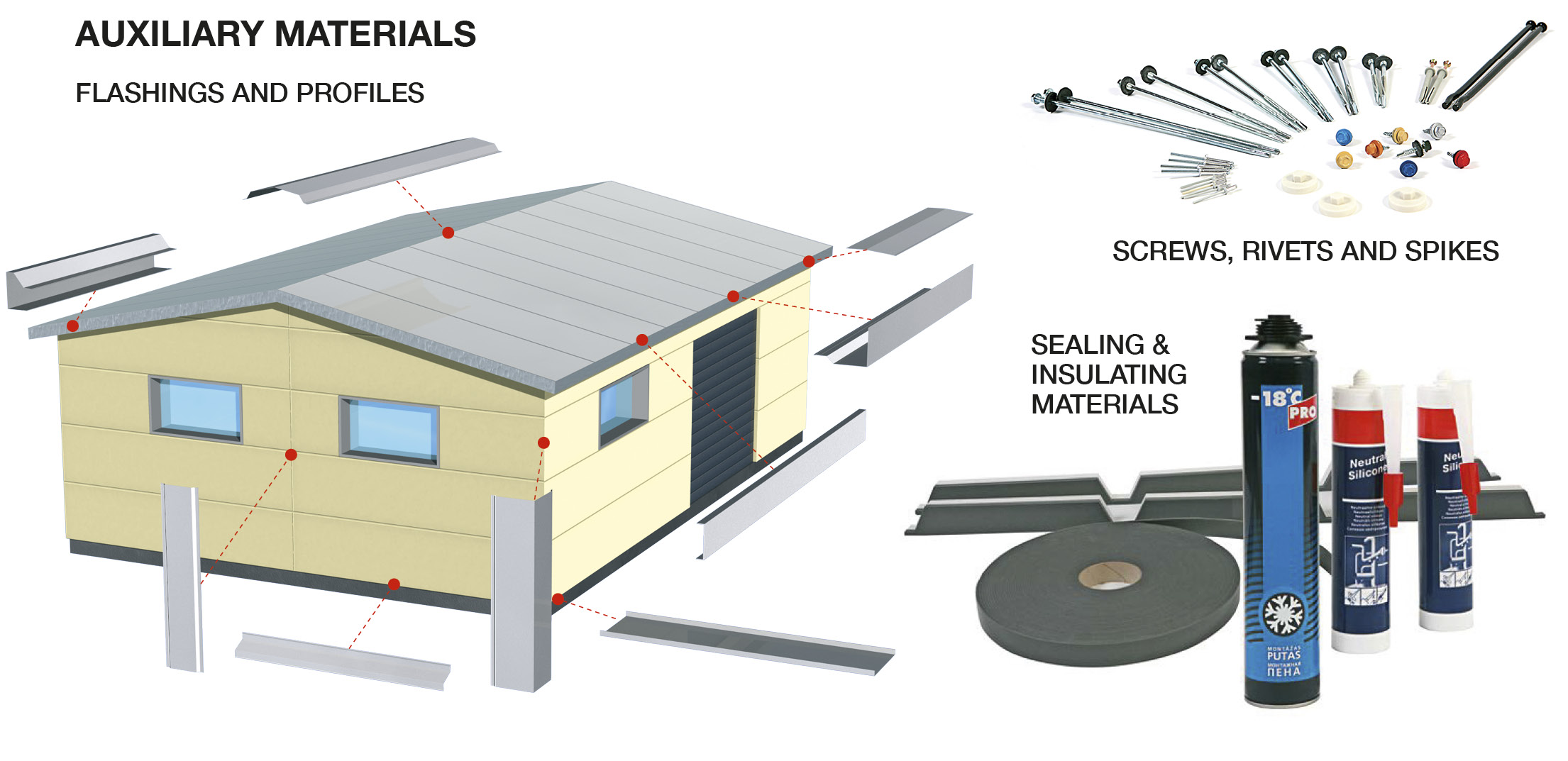

- Panels are delivered together with complementary elements (flashings, screws etc.)

- More than 10 years’ experience in production, execution and delivering of goods

No variations available for product

No product variation selected

Amount

m²

Price: + VAT

|

|

Features

- Custom made solutions

- Short delivery time (3-4 weeks)

- Engineering and designing support to clients

- Project management support during construction

- Less cutting work and waste at building site (available panel widths are from 0,6 till 1,2 m)

- Easy to replace the insulation core of panels after project design (for example, from MW to PIR)

- Panel joints are fully compatible with each other (MW, PIR, PUR and EPS)

- Panels are delivered together with complementary elements (flashings, screws etc.)

- More than 10 years’ experience in production, execution and delivering of goods

| Characteristic | Nominal value |

| Product Width / Built-in Width (mm) | 1216/1200 |

| Length, mm | 2000-13500 |

| Fire reaction (class, EN 13501-1) | B-s1,d0 |

| Fire resistance (class, EN 13501-2) | EI15; EI30 |

| Thickness, mm | |||||||

| TENAX W PIR S1 | 50 | 80 | |||||

| TENAX W PIR T1 | 100 | 120 | 150 | 175 | 200 | ||

| Weight of calculation area, kg / m2 (steel thickness 0.5 mm / 0.5 mm) | 10.8 | 12.1 | 12.8 | 13.7 | 14.9 | 15.9 | 16.9 |

| Heat permeability (U-value), W / m2.K | 0.43 | 0.26 | 0.21 | 0.17 | 0.14 | 0.12 | 0.10 |

Solutions